Cornerstones of Quality

We know how to make a single tie or a scarf. Different models, patterns and customs.

The difference between handmade and a half machined tie. Perhaps not everybody knows that there are an average of 12 operations to make a single tie. Of course you can do all the process by hand, or by machine. It influences not only the product but also on the flexibility. We like the mix between handmade and machined, because we can use the best of each, making our product original . It is these details that make the difference, and there are many, but we like to use our sixth one.

Fabrics lay and care in pattern cutting

When the fabric folds are prepared on the cutting table, every paper is overset on the other, our mattress never gets over 2.5 cm, which allows us to keep the fabric firm. The fabrics with different finishing, silk and material, are kept separately, to aid a uniformed cut and a perfect shape of the single pieces.

Cutting at 45° angle

If we cut a traditional tie or ( in many cases ) scarf, it is made on the bias. You have to try the best to respect the 45° angle is different over the pieces. Follow the materials straight line, and try to recompose that when the pieces are joined by machine. This is not always easy or possible, due to the smooth and flexible characteristic of silk.

Stripes and squares on the straight line

When we are working on stripes or a square design, from the cutting, to the lining stitching, we carefully follow the grain line. Although this is not always easy, as you work on the fabric’s reverse. We double check each tie. The result is well shown all along the side of the wide end.

Twist Test

It is quite popular and very easy to do,however not always well explained. Let the tie hang over your forearm, and make sure that its narrow end is centred against the wide end. If the cutting followed the 45° angle, and the interlining has been stitched perfectly respecting the half side all along the reverse of the tie, it will fall without twisting on itself.

The loop

A tie is usually hand stitched by a slip stitch. At both ends, the same thread should be assured through a loop, normally tied by a loop knot as a security stitch. This allows the tie to keep flexibility and elasticity, stopping the threads inside from ever opening up.

The edges on the back of the big and narrow end

When the tipping is joined to the fabric, and it is turned around, the edge clearly shows the seam allowances it followed during the construction. A quality ties must have the same straight seam allowance on both side in the wide and in the narrow head.

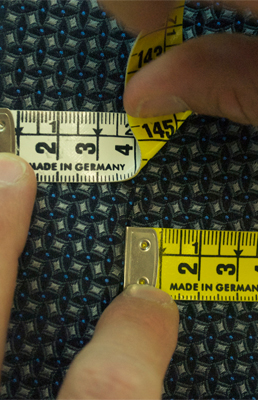

The centre line

In the half machined ties, as well as in the fully handmade items, the 45° angle shaped 2 half sides. The tie is folded in two, and the interlining must be stitched leaving the same amount of fabric on both side, all along the tie. As for the edge in the lining, this operation result is well shown when the product is turned back. Meanwhile for the handmade tie, it is possible to step by step the quality of the cut and the stitch.